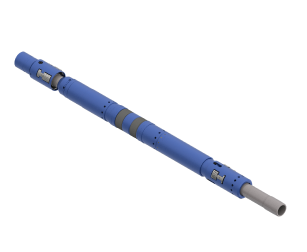

The packer is run as a part of a tubing string and installed hydraulically with conventional techniques while retrieving is achieved by straight pull to release the packer. It provides sealing between the tubing annulus and the casing in the cased hole scenario. Double slips feature enables high pressure applications. The packer release system in the upper slips reduces stress required for slips releasing. The packer is installed by applying pressure directly into the tubing, which can be plugged by dropping the ball into the seat below the packer depth or by setting the slickline plug into the profile nipple below the packer.

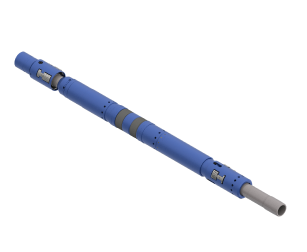

Overall length, inch

77.6

Upper thread connection, inch

API or Premium Box 2 ⅞ , 3 1⁄2

Bottom thread connection, inch

API or Premium Pin 2 ⅞ , 3 1⁄2

Work environment

Hydrocarbon / Injected fluid

Maximum working temperature, °F

340

Safe load at Тmax=350.6°F:

tensile yield strength, Rp0.2, MPa

336.2

resistance to collapse, Rm, MPa

536.4

Tensile modulus, Е, hPa

206

Nominal allowable stress (torsion), σ, MPa

206.3

Maximum outside diameter, inch

4.646

Minimum inside diameter, inch

2.382

Casing weight, ppf

15.5 – 20.0

Minimum setting pressure, PSI

2,900

Maximum inclination angle for installation, degree

90

Maximum pressure differential, PSI

10,000