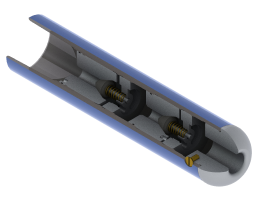

It is a configuration element of the intervention tools for the well completion. It is installed and lowered into the well as part of the pipe liner or casing, designed to guide the casing during the lowering along the well shaft and to prevent back flow of the cement slurry or drill fluid from the borehole annulus into the inner space of the casing. The nozzle and internal parts of the valve are made of aluminum alloy. The nozzle has the central and side openings.